Mechanical MRO

Will locate surface discontinuities or other indications on all non - porous materials (Metals, Plastics, Ceramics, etc.) - Cracks, Seams, Porosity, Laps, Laminations, Cold Shuts.

Used to detect welding, casting & forging defects, cracks & leaks in new - components and fatigue cracks on in - service components.

KEY FEATURES :

- Will detect wide spectrum of flaw sizes regard less of flaw orientation, up to 1 microns to 30 micron depth on standard Ni Cr test panel.

- Superior capillary action, Non - Toxic, Non-Corrosive, etc. Free from halides & sulfides, etc.

- Confirms to MIL- 1-25135, MIL STD 271, IS: 3658 - 1981 “Code of practice for liquid penetrant flaw detection“.

KEY APPLICATIONS AREAS :

Evaluation of micro surface defects & flaws in weld deposits, wrought & cast products of both Ferrous & Non-Ferrous metals, powder metallurgy parts, ceramics, plastics & glass objects.

# 7000 Flawchek Cleaner : a) Non-chlorinated solvent. b) Fast drying

# 7001 Flawchek Penetrant : a) Red ultra high penetration die. b) Specific Gravity < 1

# 7003 Flawchek Developer : a) High coverage developer b) Specific Gravity <1

PACKING : 450ml /315gms. set of 3.12 sets/ 36 cans

-

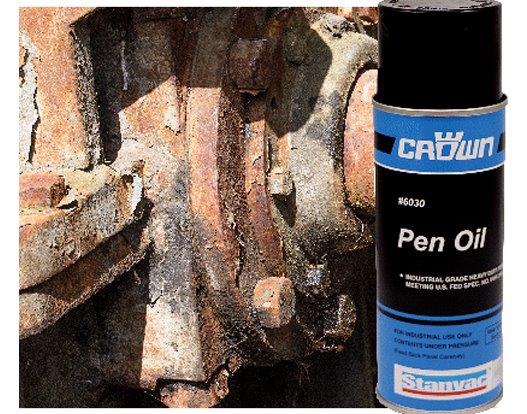

Heavy Duty Rust Penetration - #6030 Pen Oil - Best In Class Rust Penetration & Re-opening

Heavy Duty Rust Penetration - #6030 Pen Oil - Best In Class Rust Penetration & Re-opening Heavy Duty Rust Penetration - #6030 Pen Oil - Best In Class Rust Penetration & Re-opening

Heavy Duty Rust Penetration - #6030 Pen Oil - Best In Class Rust Penetration & Re-opening -

General Use - Rust Penetration, 1050 Multiuse-5 Co2 - Best In Class Re-opening & Anti Rust

General Use - Rust Penetration, 1050 Multiuse-5 Co2 - Best In Class Re-opening & Anti Rust General Use - Rust Penetration, 1050 Multiuse-5 Co2 - Best In Class Re-opening & Anti Rust

General Use - Rust Penetration, 1050 Multiuse-5 Co2 - Best In Class Re-opening & Anti Rust -

Precision Degreasing - #Z939 Bearing Solvent (NF) Co2-Sparkling Cleanliness

Precision Degreasing - #Z939 Bearing Solvent (NF) Co2-Sparkling Cleanliness Precision Degreasing - #Z939 Bearing Solvent (NF) Co2-Sparkling Cleanliness

Precision Degreasing - #Z939 Bearing Solvent (NF) Co2-Sparkling Cleanliness -

#Z197 Uniclean - Heavy Duty Citrus Degreaser - Strong Cleaning Action

#Z197 Uniclean - Heavy Duty Citrus Degreaser - Strong Cleaning Action #Z197 Uniclean - Heavy Duty Citrus Degreaser - Strong Cleaning Action

#Z197 Uniclean - Heavy Duty Citrus Degreaser - Strong Cleaning Action -

Bulk Water Dilutable Degreasers & Cleaners

Bulk Water Dilutable Degreasers & Cleaners Bulk Water Dilutable Degreasers & Cleaners

Bulk Water Dilutable Degreasers & Cleaners -

#Z914 Tough Clean - Fast Action, Non Drip Aerosol Paint Stripper

#Z914 Tough Clean - Fast Action, Non Drip Aerosol Paint Stripper #Z914 Tough Clean - Fast Action, Non Drip Aerosol Paint Stripper

#Z914 Tough Clean - Fast Action, Non Drip Aerosol Paint Stripper -

#Z82 Bulk Heavy Duty Paint Stripper

#Z82 Bulk Heavy Duty Paint Stripper #Z82 Bulk Heavy Duty Paint Stripper

#Z82 Bulk Heavy Duty Paint Stripper -

Z77 Bulk General Use Rust & Scale Remover - Ready To Use

Z77 Bulk General Use Rust & Scale Remover - Ready To Use Z77 Bulk General Use Rust & Scale Remover - Ready To Use

Z77 Bulk General Use Rust & Scale Remover - Ready To Use -

Bulk Heavy Duty - Rust & Scale Removing Water Dilutable Concentrates

Bulk Heavy Duty - Rust & Scale Removing Water Dilutable Concentrates Bulk Heavy Duty - Rust & Scale Removing Water Dilutable Concentrates

Bulk Heavy Duty - Rust & Scale Removing Water Dilutable Concentrates -

Zinc Based Anti-Corrosion Aerosols

Zinc Based Anti-Corrosion Aerosols Zinc Based Anti-Corrosion Aerosols

Zinc Based Anti-Corrosion Aerosols -

#6013 Corrosion Suppressant 101 - #Z109 Neugenic 4175 Long Term Indoor / Outdoor Use Anti Rust

#6013 Corrosion Suppressant 101 - #Z109 Neugenic 4175 Long Term Indoor / Outdoor Use Anti Rust #6013 Corrosion Suppressant 101 - #Z109 Neugenic 4175 Long Term Indoor / Outdoor Use Anti Rust

#6013 Corrosion Suppressant 101 - #Z109 Neugenic 4175 Long Term Indoor / Outdoor Use Anti Rust -

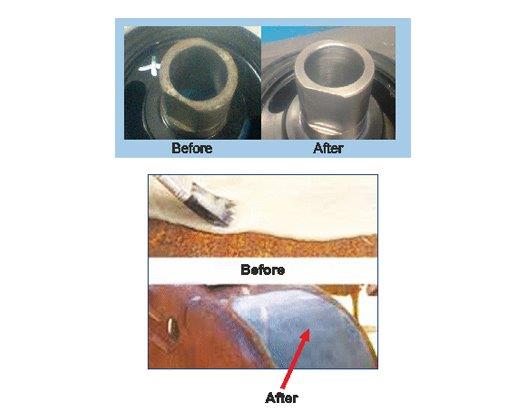

#6007 Rust Inhibitor - Precision Parts Indoor Use Anti Rust

#6007 Rust Inhibitor - Precision Parts Indoor Use Anti Rust #6007 Rust Inhibitor - Precision Parts Indoor Use Anti Rust

#6007 Rust Inhibitor - Precision Parts Indoor Use Anti Rust -

#SP98 P17 Mold Shield (Dry) - For Plastic Injection Molds

#SP98 P17 Mold Shield (Dry) - For Plastic Injection Molds #SP98 P17 Mold Shield (Dry) - For Plastic Injection Molds

#SP98 P17 Mold Shield (Dry) - For Plastic Injection Molds -

Bulk Anti Rust’s - Short Term & Ultra Long Term

Bulk Anti Rust’s - Short Term & Ultra Long Term Bulk Anti Rust’s - Short Term & Ultra Long Term

Bulk Anti Rust’s - Short Term & Ultra Long Term -

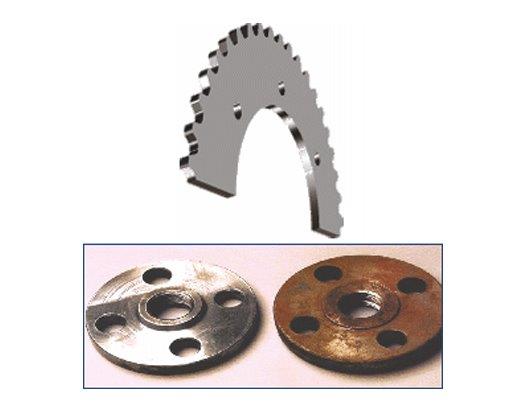

#7045 Heavy Duty Open Gear & Wire Rope Lube - Thick Penetrative + Non Drip Lubrication

#7045 Heavy Duty Open Gear & Wire Rope Lube - Thick Penetrative + Non Drip Lubrication #7045 Heavy Duty Open Gear & Wire Rope Lube - Thick Penetrative + Non Drip Lubrication

#7045 Heavy Duty Open Gear & Wire Rope Lube - Thick Penetrative + Non Drip Lubrication -

#90451 Adhesive Chain Lube - Clear Penetrative + Non Drip Lubrication

#90451 Adhesive Chain Lube - Clear Penetrative + Non Drip Lubrication #90451 Adhesive Chain Lube - Clear Penetrative + Non Drip Lubrication

#90451 Adhesive Chain Lube - Clear Penetrative + Non Drip Lubrication -

#9105 Anti Seize Compound - Thread Protection & Anti Galling

#9105 Anti Seize Compound - Thread Protection & Anti Galling #9105 Anti Seize Compound - Thread Protection & Anti Galling

#9105 Anti Seize Compound - Thread Protection & Anti Galling -

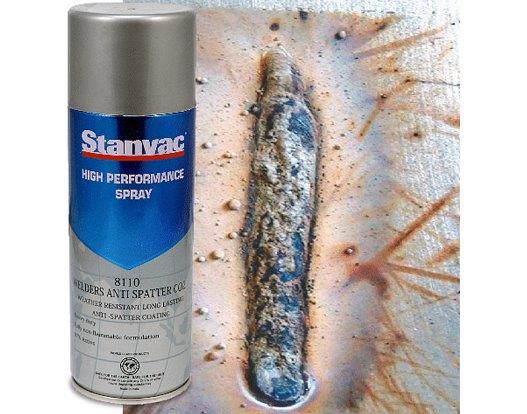

#8110 Welders Anti Spatter Co2 - Non Flammable, High Safety, High Effectiveness

#8110 Welders Anti Spatter Co2 - Non Flammable, High Safety, High Effectiveness #8110 Welders Anti Spatter Co2 - Non Flammable, High Safety, High Effectiveness

#8110 Welders Anti Spatter Co2 - Non Flammable, High Safety, High Effectiveness -

Stanvac Stainless Steel Care Spray - Cleans & Polishes

Stanvac Stainless Steel Care Spray - Cleans & Polishes Stanvac Stainless Steel Care Spray - Cleans & Polishes

Stanvac Stainless Steel Care Spray - Cleans & Polishes -

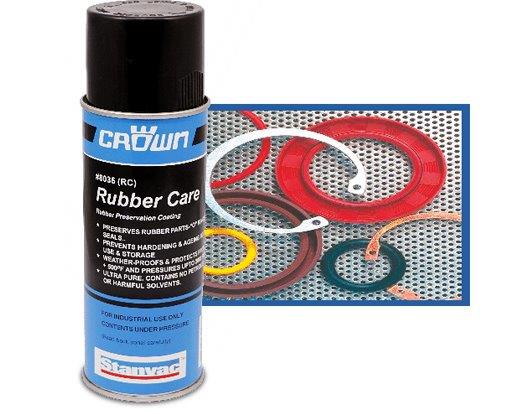

#8035 (RC) Rubber Care-preserves & Protects Rubber Parts

#8035 (RC) Rubber Care-preserves & Protects Rubber Parts #8035 (RC) Rubber Care-preserves & Protects Rubber Parts

#8035 (RC) Rubber Care-preserves & Protects Rubber Parts