731 ER Extreme

High Performance zirconium-Ceramic filled epoxy erosion resistant system for metal protection. against pulverised coal, Flyash slurries...

FEATURES :

- Excellent erosion resistance.

- Ceramic-Zr filled matrix

- Rebuild worn-out surfaces fast. Enhances component life minimum 7 times.

- >10000 hrs salt spray

- Excellent sag & shrink resistance.

USP’S :

- Highest surface hardness - unable to grind with abrasive wheel.

- Tabor abrasion results <2mg/1000 cycle.

- High Performance macro Zr-ceramic & re-inforced material filled epoxy system.

- Very high wear, cavitation, erosion & corrosion resistance.

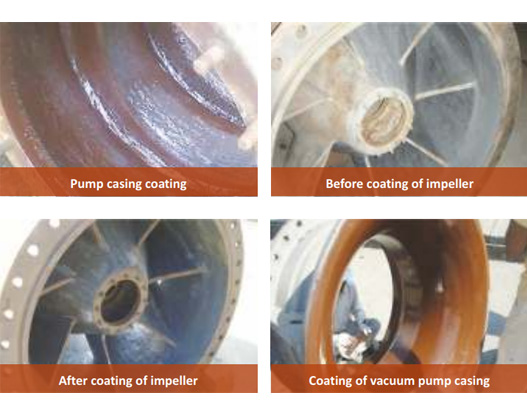

- Ideal for pulverised coal, limestone, cement, flyash, slurry-lines, pumps, hoppers, slides.

KEYAPPLICATION AREA’S :

Equipment, pipes and ducting, pump housing, VRM, coal injector valves, pipe line bends ( Lbend,Y-bend,T-bend, reducers etc), power plant, chemical plants, pulp and paper mills, cement industries, mining, steel industries & ash handling pipes and valves, coal pulverisers, exhausters, screw conveyors....

Request Form